Shot Blast and Tank Lining

REDS Surface Preparation team completed a full blast and lining of an underground storage tank (UST) for a telecoms and data client in London, prior to refuelling with a different grade of fuel.

Project Scope

The tank was blasted with medium-grade Iron Silicate to achieve the recommended surface profile of 70 microns (µm), before applying the lining product, Jotun Tankguard Storage, per the manufacturer’s application guidelines.

Project Works

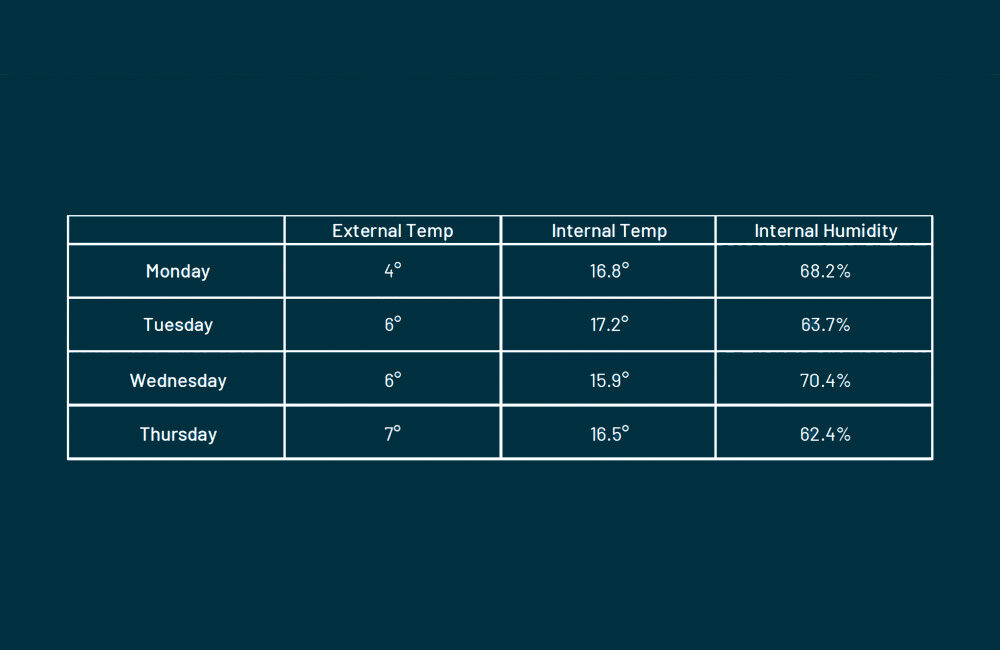

Temperature and humidity readings were taken on site daily.

Dew point was generally 8° lower than the surface temperature, well within the acceptable conditions for the task at hand.

The team carried out precision blasting, using positive air pressure helmets, PPE, and rescue equipment. The operation included cleanup and the application of a 40μm holding coat, followed by a stripe coat on the welds to prevent oxidation of the newly cleaned steel.

In the initial phase, technicians applied the first full coat using airless spray, operating under strict safety standards with air-fed masks and rescue equipment on standby.

Wet film thickness was tested, ensuring it fell between 250-275μm using a wet film comb, aligned with the upper end of the manufacturer’s specifications.

The second coat was also applied with a consistent thickness of 250-275μm, thoroughly tested to meet quality standards. No thinners were added, and the percentage solids met the manufacturer’s specification of 63%, further reinforcing the commitment to quality.

Results

The average theoretical dry film thickness was 340μm, while actual readings taken after full curing averaged 362μm. Measurements were taken at various random locations in the tank, including the central plate, 15mm from welds, and on welds.

A full visual inspection revealed no transparency, shrinkage, or inclusions in the coating. Subject to any remedial pipework, the lining is now fit for service.

REDS offer expert surface preparation services for your fuel assets.

We specialise in sandblasting, tank lining and repairs, cold welding, bund lining and repairs, thermal spraying, and commercial painting to ensure the longevity of your assets.

Related Case Studies